What Are Rubber Dampers and How Do They Work?

Rubber dampers are key components for effective vibration absorption and shock mitigation in various industries. Rubber shock absorbers are made of high-quality rubber that allows elastic adaptation to loads and protects machines and devices from damage. In this article, we will explore in detail why rubber dampers are indispensable in modern manufacturing and how they work.

The Importance of Rubber Dampers in Industry

Rubber dampers provide effective vibration damping, meaning they absorb vibrations generated by the operation of machines, conveyor belts, engines, or other mechanical systems. If system components wear out too quickly due to constant vibrations, it can lead to bearing, clutch, or even major component damage. The use of rubber shock absorbers significantly extends the equipment’s lifespan by reducing mechanical stress and wear processes.

In industry, rubber dampers are used in various places:

- In conveyor belts as cushions between metal parts.

- In engine mounting to prevent vibration transfer to the frame.

- In presses and machines with strong vibrations to protect sensitive parts.

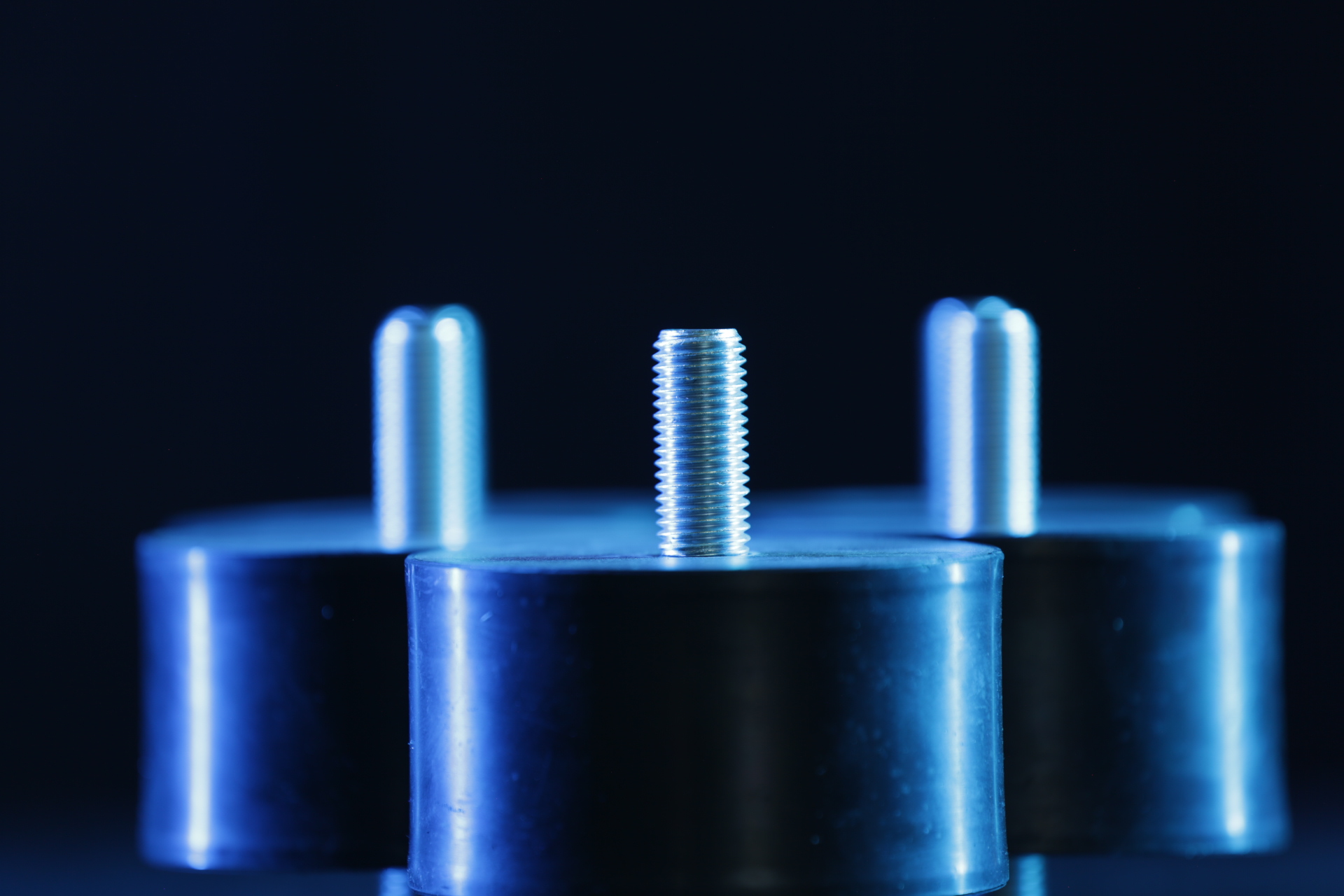

Construction and Materials of Rubber Shock Absorbers

Rubber Selection

The rubber used in dampers must have appropriate properties of hardness, elasticity, and resistance to temperature changes. At Tech-gum, we use various compounds tailored to the specific requirements of the final environment. Some compounds offer better vibration dampening at higher temperatures, while others resist chemicals or oils.

How Do Rubber Dampers Work?

Operating Principle

When the system is loaded or a shock occurs, rubber compresses and absorbs the kinetic energy that would otherwise transfer to machine components. Thanks to its elastic properties, the rubber returns to its original shape after the load is gone, dispersing the energy wave.

Vibration Damping

Vibration damping occurs through a combination of the rubber’s viscoelastic response and internal friction. This process converts mechanical energy into heat, which dissipates into the surroundings, reducing vibration amplitude and protecting sensitive parts of the machine.

Conclusion

Rubber dampers are indispensable for all industrial systems where vibration damping and machinery protection are essential. Using high-quality rubber shock absorbers extends equipment lifespan, reduces maintenance costs, and improves operational safety. When choosing a damper, it's important to consider the type of rubber compound and damper design to ensure optimal performance and reliability. For more information about Tech-gum products and applications, contact us today!